Our customer, a small fleet owner and Diesel sales 2017

In 2017 we were approached by a small diesel retailer that supplied diesel to telco BTS’s, banks and some small to medium size industries in Lagos. They had been referred to us by a one of our larger clients (WiHu) with over 80 engines in their portfolio. They had heard about the 80 to 90 % cost savings we had been able to achieve and wanted to replicate it with their smaller fleet of 6 trucks and 2 office based generators some engines had light white smoke from the exhaust. We began with testing the oil they currently used, to establish a baseline, which was a mineral diesel oil 15W40 (New oil was a No 4 on the Lubricheck), 5 trucks were all a numbers 8 to 10 (oil had sludge) when we tested them only some of their odometers were working so it was hard to capture accurate distance travelled data.

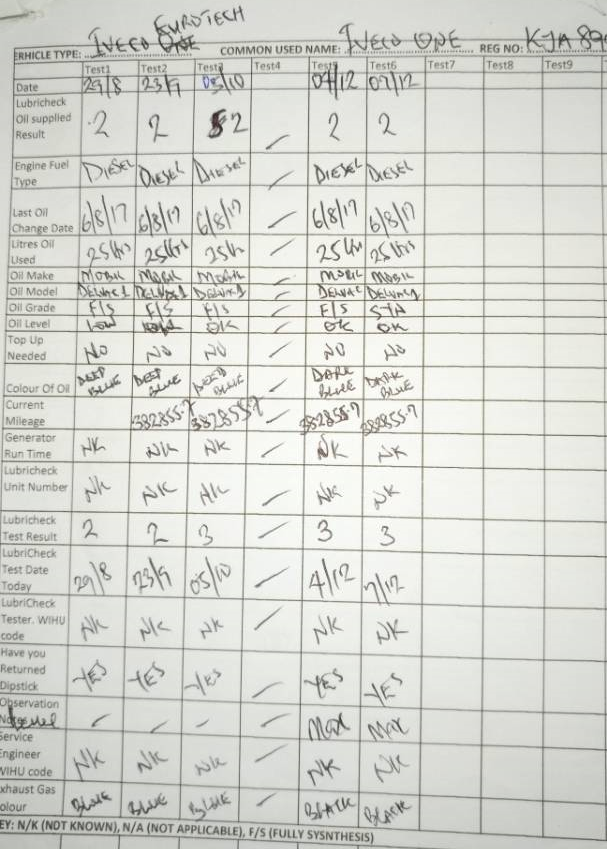

We found that the 15W40 would last about a 2 to 4 weeks (with 8hr/day traffic) depending where the truck traveled to within Lagos. We introduced the Mobil Delvac 1, 5W40 fully synthetic oil (No 1 on the Lubricheck) and found the oil to last over 6 months with the same routes as before and the 8hr/day traffic). See a sample audit sheet below of a 4 month:

The company wanted to self-manage their lubricheck oil analysis program, so we trained their team to collect data and provided an audit form template.

One of the fantastic results we get from collecting the right data when auditing engine oil quality using the Lubricheck is being able to identify potential issues such as:

- Is the engine oil being used a good oil or substandard (fake, adulterated, bad) oil.

- How long does the oil last in an engine (Miles, KM or Hours).

- With knowing how long an oil lasts in an engine we can profile different oils, to determine which oils are the best for an engine and how much, in terms of cost, will that oil save a customer.

- How much do we save in engine oil servicing costs (oil and filter change frequency, time engine is not in use, labor, accidental mechanic damage each time the engine is accessed etc).

- Is the engine loosing oil regularly and by how much?

- If the engine is losing oil is it from an engine oil leak or is the engine worn and burning oil excessively.

- Which person did the oil test and with which Lubricheck device?

- Has the Lubricheck device lost its calibration? This happens occasionally when the person testing the oil does not follow the instructions on how to use the Lubricheck.

- Was the Lubricheck device cleaned properly before the test? We recommend 2 or more units are used to test engine oil from any engine. There may be a small variation in results, but when you test and oil and you get a 1 with one device and a 10 with the other. It could mean either one device has lost its calibration or the unit was not cleaned properly. Usually with historical data collected on earlier engine oil tests this issue can easily be identified.

- If an engine needs to have it oil topped up this could also change the results on a Lubricheck. If the oil that was used to top up is a good oil of say a number 1 and it is added to an engine that has used oil that shows a number 3, then depending on the quantity of oil added, you might find the new Lubricheck tests result showing a number 2 or 1. If however you top up the same engine (with oil a No 3) with a bad oil of say a 8, 9 ,10 you might find your new test results showing and 8,9 or 10.

- You can also identify if the person collecting the data understands what they are collecting and if they are entering data correctly or just entering data so it looks like they are doing their job.

It was with analyzing data collected that we able to identify a number of problems with engine use and management. Two incidents that stood out were:

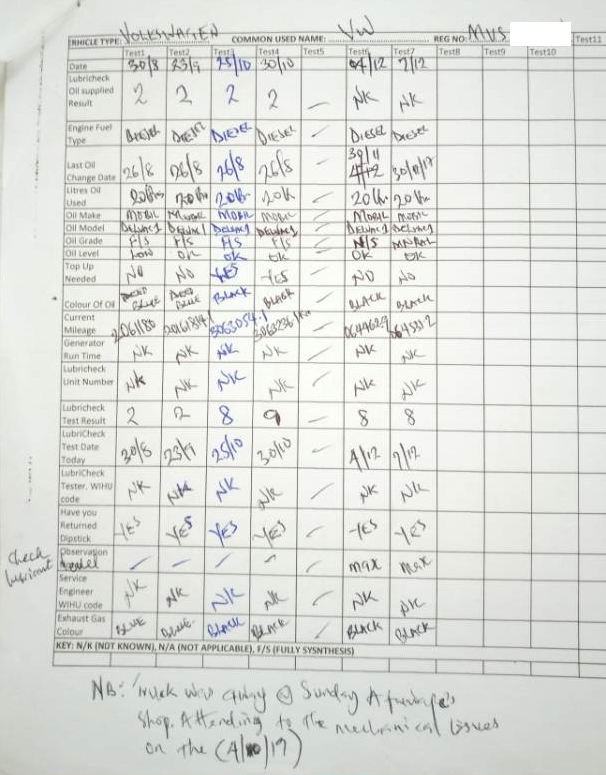

- The company had a small 14,000 liter diesel supply VW truck that had been using our recommended Mobil Delvac 1 (5W40) engine oil. This was an oil that we had doing 10,000 to 17,000 miles in trucks in with other customers. They had already decreased they service costs by almost 80% using this oil in each truck for up to 6 months and were wondering why after 2 months and 2300 + miles, this truck was showing a Lubricheck result of 8 and 9. Even after an oil change, the new oil still tested an 8 on their Lubricheck.

Initially we thought the Lubricheck unit had lost is calibration so we asked them to test oil from another 2 trucks that had the Delvac 1 oil in their engines, the trucks returned results of 2 and 3 which was what we had expected from the time and distance the oil had been in these engines. With this we knew that the Lubricheck unit was working well.

We then asked for the audit sheet to be sent to us. When we received it we could see straight away that the engine oil had been topped up after 2 months and it was this top-up that brought down the quality of the oil in the engine from a 2 to an 8. We noticed that about 6 weeks later the engine had its oil changed and that the new oil was a number 8. Our Delvac 1 oil was always a number 1 or at worst a number 2 (if the device was not cleaned properly). We also noticed a note at the foot of the audit sheet that implied that the first top-up was done at a 3rd party mechanic workshop.

It was at this stage we began to ask questions about the oil used to top up. This was when the full picture of what had happen came to light. The in-house mechanic had left and the truck was taken offsite to a 3rd party mechanic who used his own recommended (SAE 40 mineral) oil to top up the engine and change the engine oil 6 weeks later. The person inputting data on the audit form never check to find out what oil had been used and just kept on copying the Delvac 1 (5W40) entries he had seen from earlier entries. See below a copy of the audit sheet:

We had seen in-house mechanics leave once companies begin to use our solution of recommended oil and implement the Lubricheck to audit the quality of the oil. As the company begins to make their 80 to 90% savings in engine oil service costs, the avenue for the in-house mechanic to make his every 2 to 4 week side money from each oil change for each vehicle; stops.

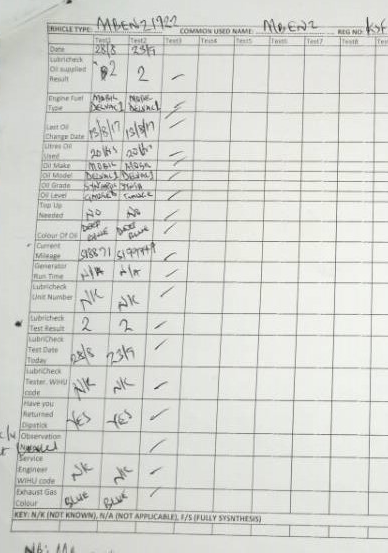

- The company also had a Mercedes Benz truck used to deliver diesel to customers. We were called and told that our oil had caused the truck engine to knock. We were shocked because this was the first time Mobil Delvac 1 (5W40) oil had had any issues.

We asked for the truck’s Lubricheck audit sheet and saw that the oil was still in very good condition (Lubricheck No. 2) for the earlier 2 months before the engine knock. We tested the oil in the knocked engine and it was a number 10 on the Lubricheck. We asked if the engine had overheated but the driver said no and insisted that the engine just started making a knocking noise and so he turned it off. The engine service team confirmed that the engine had never been topped up and only Delvac 1 was in the engine. See audit sheet below:

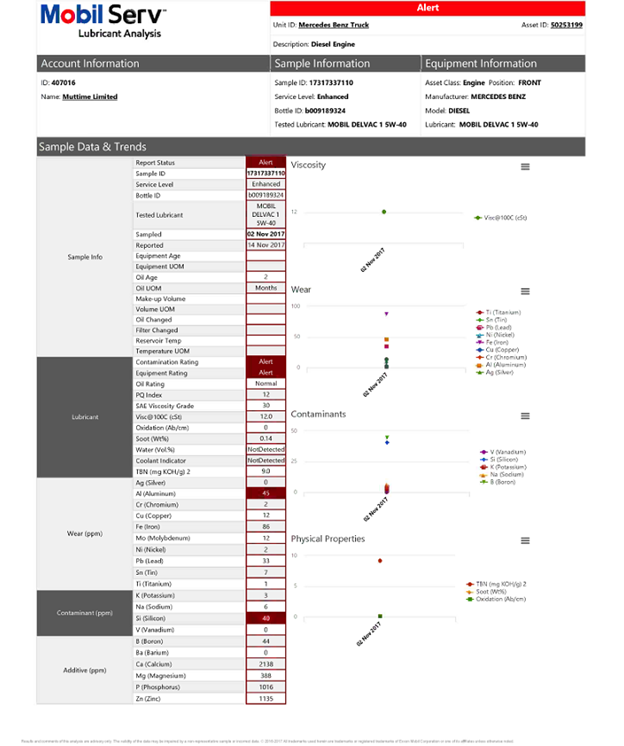

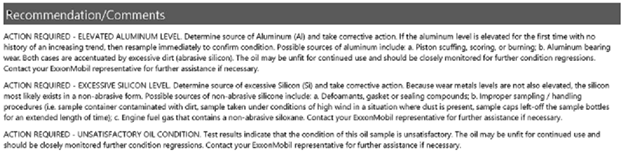

We spoke to Mobil and narrated what had happened they insisted that it was very unlikely that Delvac 1 oil was the cause of the knock especially since the engine had done less than 2000 miles. We were asked to send in a Sample for Analysis, see report below:

With another 3 Lubricheck units used to test the knocked engine oil showing a fast flashing 10 in each case and the Mobil oil analysis report we confronted the driver who finally confessed that he was in heavy traffic and there was an explosion in the engine and steam began to come out of the engine. He did not want to stop where explosion happened as there were LASTMA (Lagos state traffic management Agency/wardens) who he was afraid would seize and tow his truck. He did not want to pay a fine so he decided to drive down the road in traffic. He said the engine started making a knocking noise while in traffic and he turned off the engine. He filled up the radiator as it was empty and started the engine but it was still making the knocking noise until the engine suddenly went off.

The Lubricheck as you can see, not only helps companies save money but also with the right data collected for each test can help in building the full picture of what actually happens/happened to an engine.